In recent years, many foreign companies have chosen China as their ideal location to settle their research and development (R&D) centers to cater to the vast Chinese market demands and serve a larger global market.

In late July, THE LAUNDRESS, a high-end fabric care laundry brand affiliated with the global consumer goods giant Unilever, unveiled its Asia R&D Center in north China’s Tianjin Municipality.

The R&D center is inside Unilever Tianjin Industrial Park, which aims to give full play to the effectiveness and safety of the local manufacturing base.

Thanks to the leading technologies of China’s intelligent manufacturing, the filling speed of its new production line is estimated to be significantly improved, and transportation efficiency is expected to soar by 90 percent. The comprehensive support of the local supply chain can also better ensure the quality and stability of products from the source, said the company.

“We have seen exceptional demand for our products in China since the launch in 2019. The opening of the R&D center in China shows our commitment to fostering local innovation and tailoring products that cater even better to the needs of our valued customers in this dynamic and thriving market,” said Clemens Herrmann, CEO of THE LAUNDRESS.

As the relevant industry sectors develop rapidly in China, Unilever is not alone in shifting to localized production and leveraging the advantage of China’s intelligent manufacturing.

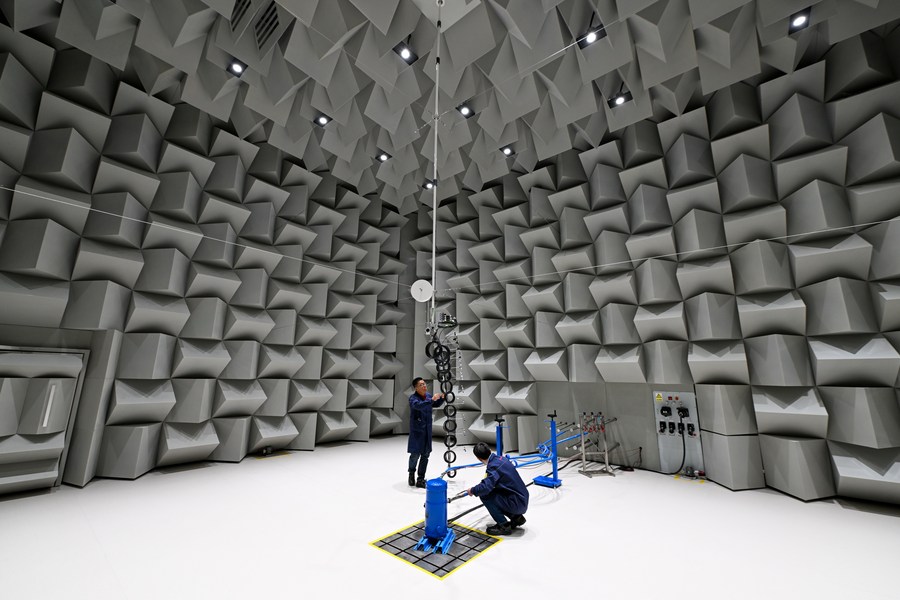

Mounted on the ceiling and walls, numerous anechoic wedges made the room with low ambient noise a bit eerie but brimming with a striking sci-fi atmosphere.

In the center of a testing room, a compressor does the major work, with over 10 detection sensors positioned above it capturing acoustic signals from multiple angles, while the control center receives and displays real-time compressor noise data.

The laboratory is the global refrigeration industry giant Danfoss’ most advanced and largest scroll compressor R&D and testing center in Tianjin.

This photo taken on May 10, 2023 shows staff members working at a testing room at the Danfoss Global Green Refrigerants Compressors Laboratory in Tianjin, north China.(Xinhua/Sun Fanyue)

“The R&D center conducts dozens of projects each year,” said Duan Chenjun, head of the center. The tested and validated technologies and solutions will find widespread applications in many sectors, such as air conditioning, data centers, cold chain, and energy storage, Duan added.

Arthur Xu, president of Danfoss China, said it is significant for the group to move from “producing” in China to “creating” in China, which reflects the company’s confidence in China’s green development and the long-term prospects of the Chinese economy.

Over the past 27 years, Danfoss has set up 12 factories and 26 sales locations in China. China is the company’s second-largest market globally and largest source for procurement. In 2022, the sales volume of the company in China reached about 10 billion yuan (1.4 billion U.S. dollars).

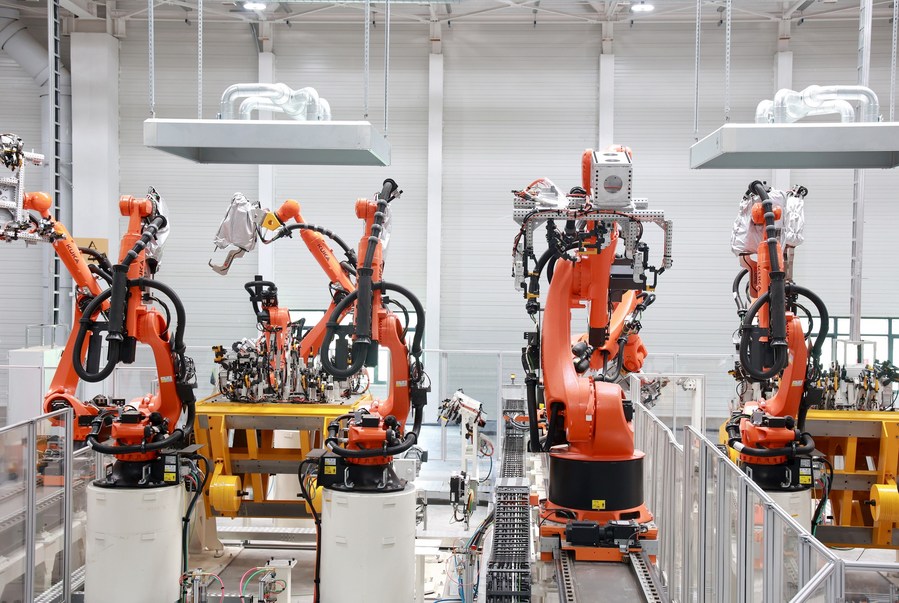

Likewise, German carmaker Volkswagen Group set up a technology company with a total investment of about 1 billion euros in Hefei, the capital of east China’s Anhui Province, in May, as its R&D, innovation, and procurement center for new energy vehicles (NEVs) and intelligent connected vehicles in China.

Moreover, in March, global water technology provider Xylem put its R&D center in China into operation, while French multinational Schneider Electric launched its automation R&D center in Wuxi City, Jiangsu Province. In May, a new Volvo car design studio, among its total of three design studios over the globe, opened in Shanghai.

This photo taken on July 4, 2022 shows a workshop of the Volkswagen Anhui MEB (Modular Electric Drive Matrix) plant under construction in east China’s Anhui Province. (Xinhua)

In the past, foreign investment in China targeted the massive potential of the Chinese consumption market. But more and more foreign investors build R&D centers in China now, testifying to China’s well-recognized innovation ability.

Many multinationals have strived to consolidate their business capabilities and seize the initiative to gain worldwide development with the help of China’s industry-university-research cooperative innovation ability and diversified industrial talents.

Hu Xiao, senior vice president of Schneider Electric, said with more industrial talents, the company’s R&D center built in Wuxi can better meet the needs of China’s local customers and, in the meantime, serve a larger global market with a more agile innovative organization and a stronger local collaborative innovation capability.

Since the beginning of this year, China has further strengthened its efforts to attract foreign investment by launching a series of business promotion activities.

Chen Chunjiang, assistant minister of Commerce, said that foreign-funded R&D centers are important parts of China’s scientific and technological innovation system, which has made positive contributions to the introduction of international cutting-edge technologies and high-end talents, the upgrading of industrial technology levels and scientific and technological innovation capacity, promoting the rapid development of the global industrial chain and innovation chain.

Shayne Heffernan